Date:2019-09-29 Categories:Industry News Hits:443

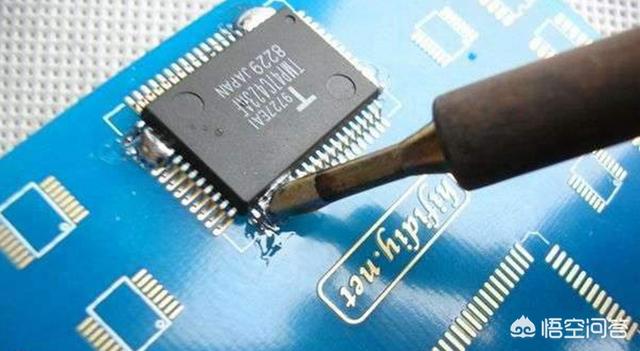

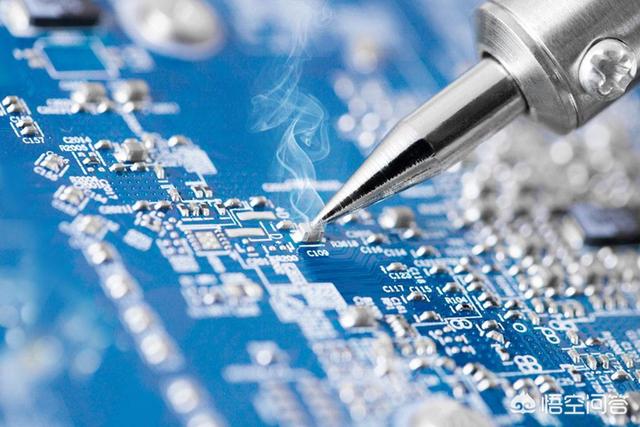

In the initial stage of debugging and maintenance of circuit board, the replacement of components and parts will be encountered. Disassembling components is a kind of labor with technology. If you don't pay attention to it, it will lead to the damage of the disassembled components and even the solder pad. Electronic components are sensitive to temperature. If the temperature is too high and the electric soldering iron stays for a long time, the components will be damaged, resulting in the replacement of other boards. This damage may be local damage, some functions are intact, some functions are wrong, which leads to the difficulty of debugging.

What problems should be paid attention to when disassembling components?

1. The temperature of electric soldering iron should not be too high and the residence time should not be too long

The higher the temperature of the electric iron, the easier the solder melts, but it is also more likely to damage the chip. Therefore, no matter what kind of package is disassembled, the soldering iron should be adjusted in real time.

2. Cooperate with the use of various tools

When dismantling, it is not enough to rely on electric soldering iron alone. It is necessary to use tweezers, air guns and tin absorbers. For the chip with fewer pins, the electric iron can be very competent. If it is a multi pin package, such as lqfp100, it is best to use a hot air gun to blow. When blowing, pay attention to the temperature and wind speed, and the air gun will keep moving. If it is the in-line package with more pins, it needs to use a solder sucking device.