Date:2019-02-14 Categories:Industry News Hits:616

Electronic products, there is an important link is the heat treatment, now many products are small and thin, the heat dissipation requirements will be very high, for example, notebook computer, is a very compact, for the cooling vent must be designed reasonably, today captain shonway will share with you about how to deal with the heat dissipation of circuit board. The method is simple, but the effect is very good

1. Increase the copper cover of the heating chip

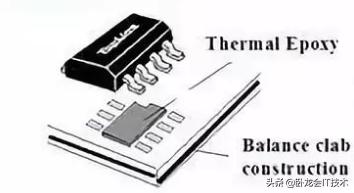

This is to add a large copper skin under the heating chip to expose the copper skin. The lead skin should be exposed on both sides. The heat dissipation pad of the chip should be welded on the front side, and then holes should be drilled to connect with the large copper on the back side. The heat can be dissipated through the copper sheets on the front and back sides.

As shown in the figure above, there is a thermal epoxy under the component package, which is the heat dissipation pad. Some vias will be punched on the pad. The copper sheet on the reverse side can be made larger. The larger the area, the better the heat dissipation

2. Heat dissipation through hole

It is said that a through hole should be made on the heat dissipation pad. This is the heat dissipation through-hole, which connects the upper and lower copper sheets. The heat can be transferred from the front through the heat dissipation hole to the large copper skin on the reverse side. The more the vias, the better the heat dissipation. The via temperature of 6x6 matrix can be reduced by 2,3 degrees compared with that of 4x4 matrix. The effect is still good.

The size of the vias is a little particular. The vias should not be too large. Generally, they should be less than 0.3mm, so that the tin on the front pad will not flow to the bottom layer easily because of melting.

3. What should we pay attention to in terms of layout

Layout is an important part of heat dissipation, and the following points should be paid attention to

1. The high heat element should be placed in the vent and cold air area

2. If there is a temperature sensor, these components must be placed in the hottest place of the circuit board. This makes it easy to detect board temperature.

3. The high heat element should be placed on the edge of the board, so that it is closer to the outside air. If placed in the middle, the heat conduction distance is large and the heat dissipation is slow

4. For some components which are sensitive to heat, such as small current transistors, electrolytic capacitors and so on, the performance of these components will be affected if they are heated. These components should be far away from the heating elements

5. Consider the flow direction of the air in the board as a whole, and where the product is placed. The location of the air is how to flow to think well. According to the direction of air flow, reasonable configuration of various components

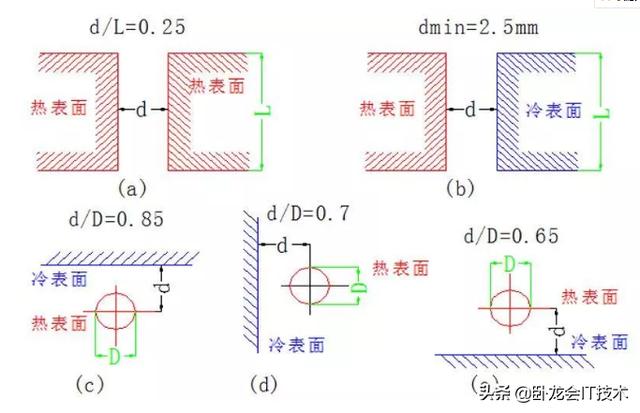

6. It is recommended to set the spacing of component layout according to the following method.