Date:2018-05-29 Categories:Industry News Hits:490

Disassembly method of printed circuit board

1. Disassembly of components on single-sided printed circuit board: toothbrush method, screen method, needle method, tin absorber, pneumatic gun and other methods can be used. A detailed comparison of these methods is given in Table 1.

Most of the simple methods for dismantling electronic components (including advanced pneumatic gun) are only suitable for single panel, but not for double-sided panel and multi panel.

2. Disassembly of components on double-sided printed circuit board: single side integral heating method, needle tube hollowing method and tin flow welding machine can be used. The single connected integral heating method needs special heating tools, which is inconvenient for general use. Needle tube hollowing method: first cut off the pins of the components to be removed, and then remove the components. At this time, the pins left on the printed circuit board are the cut pins of the components. Then, melt the tin on each pin with a soldering iron, and take it out with tweezers until all the pins are removed. Then, the medical needle suitable for the inner diameter of the pad hole is used to empty it Process, but no impact on the printed circuit board, easy to get materials and easy to operate, I think it is an ideal method after years of practice.

3. Disassembly of components on multi sided printed circuit board: if the above methods are adopted (except for tin flow welding machine), it is not difficult to disassemble, or it is easy to cause the connection fault between layers. Generally, the soldering method is used. The components are cut from the root of the pins of the components, leaving their pins on the printed circuit board, and then the pins of the new devices are welded to the pins left on the printed circuit board. However, it is not easy to weld the manifold block. Tin flow welding machine (also known as secondary welding machine) can solve this problem. It is the most advanced tool to dismantle the integrated blocks on double or multi-layer printed circuit boards. But the cost is high, and thousands of yuan is needed to be invested. Tin flow welder is actually a kind of special small wave soldering machine, which uses a tin flow pump to extract fresh and non oxidized molten tin from the tin pot, and forms a local small wave peak which acts on the bottom of the printed circuit board. The solder of the pin and the welding hole of the removed components on the printed circuit board will melt immediately in 1-2 seconds, The component can be pulled out gently, then the welding hole of the component is blown through with compressed air, the new component is inserted again, and the finished product is welded on the crest of tin spray port.

Of course, in addition to the above, there are other methods (such as copper wire method, alcohol lamp method, etc.), but because of their no prominent characteristics, they are similar to the methods described above, so we will not talk about them here.

In our daily life, most of the household appliances we use are single panel. Although all kinds of simple methods have their own characteristics, it is recommended to use a tin absorber. For double and multi panel, the simple method mentioned above can be adopted, which is economical and feasible. It is better to use tin flow welding machine.

Detailed procedures for IC disassembly on double sided circuit board

You may have been encountering a problem, that is, the disassembly of multi pin components on dual sided PCB! (the 2-pin components should be easier to disassemble)

In the personal welding exploration, it is found that the hot air gun is very useful for the disassembly of IC of double-sided panel. The method is introduced as follows

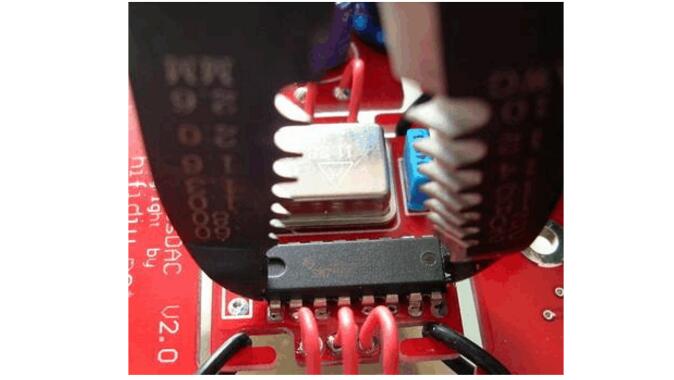

The IC removed this time is a 16 pin dip package IC

The tools used are: hot air gun and pliers

The part to be removed: (16 pin IC in the figure)

First clamp both ends of IC with pliers:

Turn on the hot air gun, adjust the temperature to 380 degrees, and adjust the wind force to 80% position to evenly heat the IC pin on the reverse side of PCB!

Heat uniformly according to the above figure. It is estimated that after heating for 10 seconds, quickly pull the pliers out, and the IC will come out without damage in general!

In this way, the disassembly of the whole IC is completed. However, when I look at the IC hole of the double-sided board of the removed IC, the connector is also large. When I was about to drill the hole on the PCB with a small electric drill, I accidentally looked at the hot air gun, and an idea suddenly came into being: hit the IC pin hole on the double-sided PCB with the maximum wind!

It's so effective! The whole hole is completely empty!

The whole IC is very easy to replace!